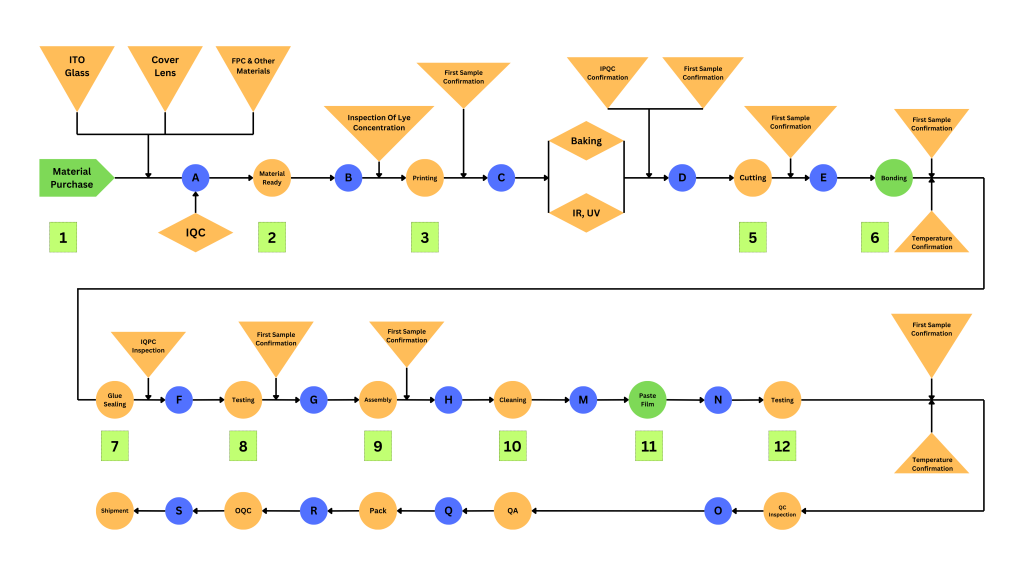

Quality Control

We pledge to deliver excellent quality, continually meet customer expectations, relentlessly pursue excellence, and never cease to advance

Longwin is committed to continuous improvement in quality control. We not only aim to meet industry standards but strive to exceed them. We constantly assess and refine our quality management processes, seeking opportunities for improvement to ensure our products and services consistently perform at the highest level. We collaborate closely with suppliers and partners to establish and implement best practices, and invest in advanced technology and equipment. Through training and nurturing our team members, we foster a culture of innovation and continuous improvement, ensuring our ability to stay competitive in evolving market dynamics and deliver the highest quality products and services to our customers

Longwin is recognized by ISO 9001, ISO 14001 and has received IATF 16949, which meets ROHS/REACH environmental rules in global markets.

Key-points of quality Inspection

Dirtiness

Ink Adhesion

Reliability

Flatness

Static Electricity

Glass Material

Surface Hardness

Dimensional Accuracy

Response Speed

Operation Speed

Black/White Dot

Broken LineGray Scale

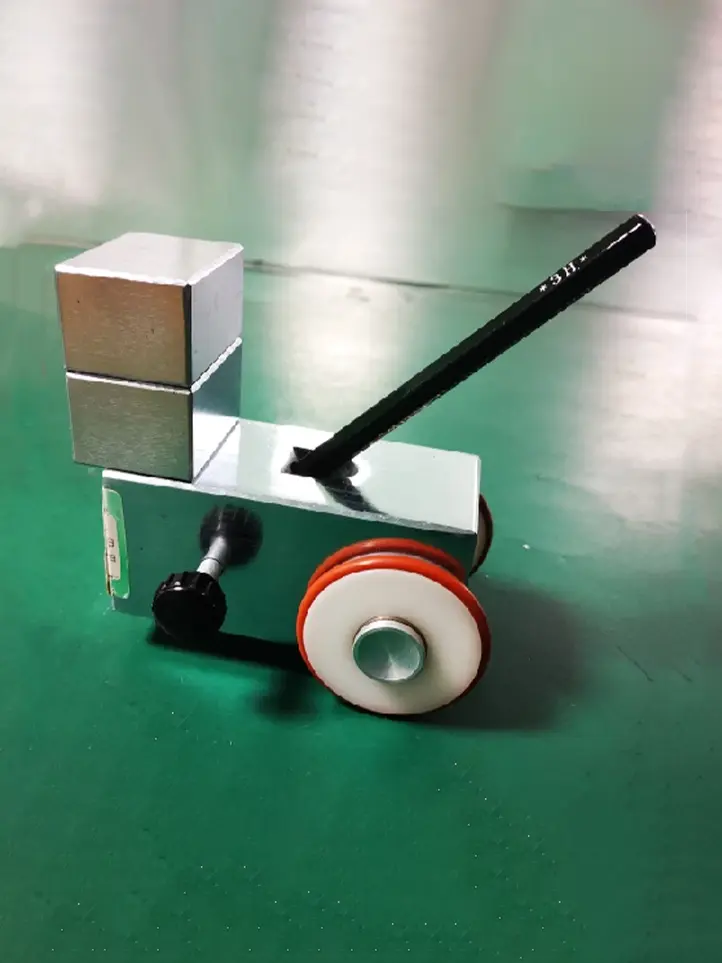

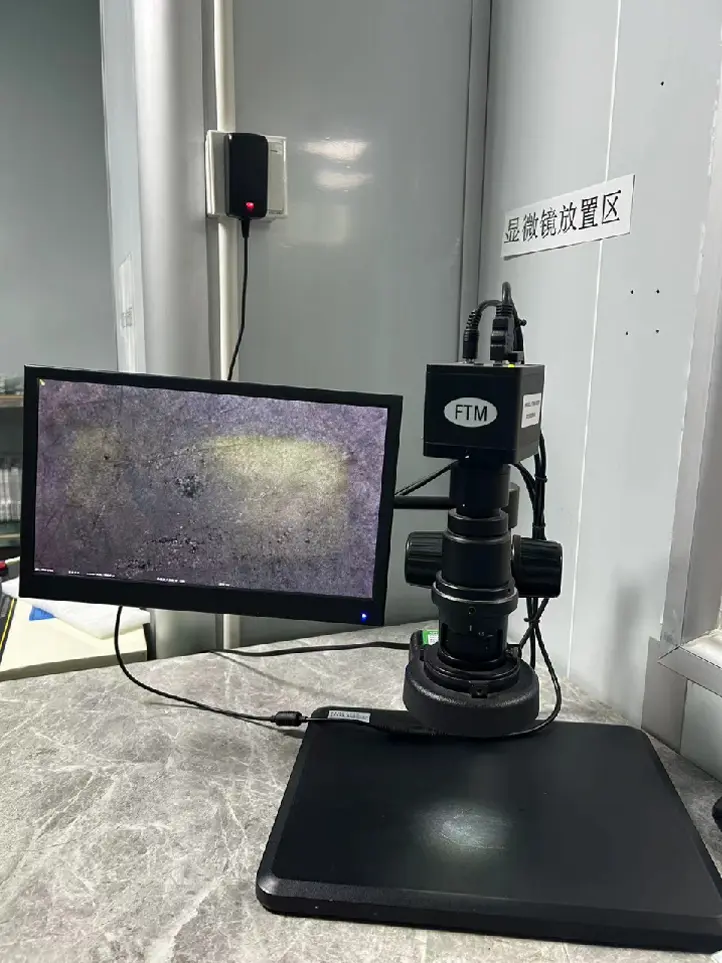

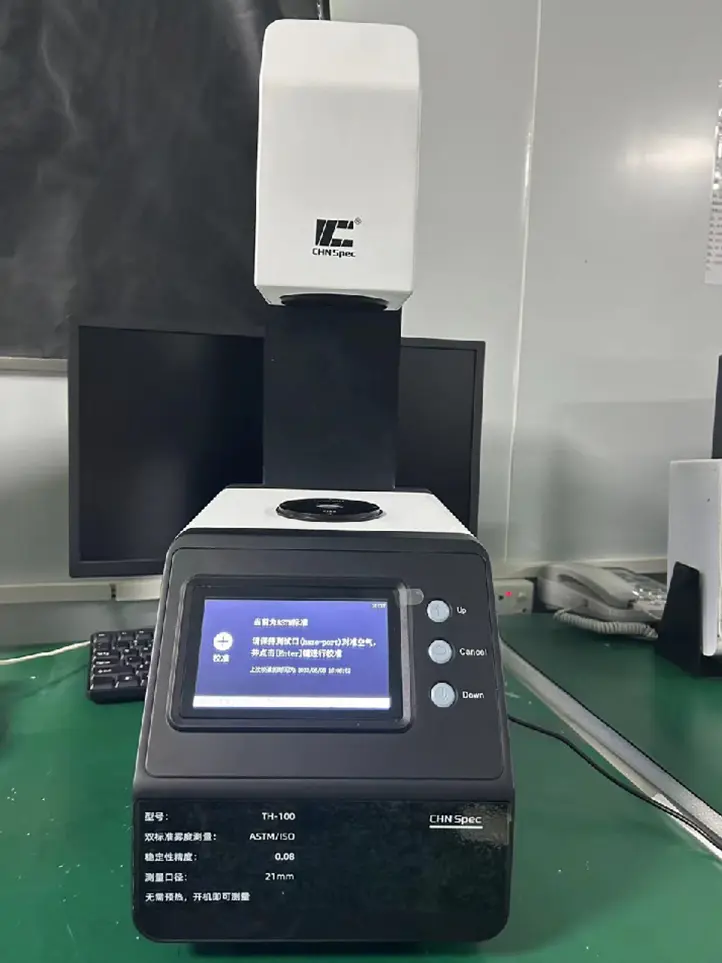

Test Equipments

- Static High Voltage Tester

- Tensile Testing Machine

- Drop Ball Test Apparatus

- Spectrometer

- Hardness Tester

- Barrier Property Testing Instrument

- Infrared Thermometer

- Contact Angle Tester

- Two-dimensional Measuring Instrument

- Constant Temperature and Humidity Chamber

- Salt Spray Tester